From the time Eskil W. Swenson was granted his first patent in 1938, innovation was at the heart of his company. After 35 successful years in the spreader business, Eskil retired in 1974. During this time, Eskil Swenson and Swenson Spreader Manufacturing were issued more than a dozen patents and contributed to innumerable innovations.

Hearing from the people who knew Eskil “Eck” W. Swenson, one theme comes through clearly: Meeting Eck was meeting a true innovator. It meant encountering someone who wasn’t just creative on occasion or during an 8-hour shift, but someone driven by relentless curiosity, simply because he didn’t know any other way to be. Eskil’s journey was that of a pioneer. His impact continues to shape our industry. Learn how Eskil Swenson’s remarkable career helped shape an industry, and how his influence continues to be felt today.

1923: A young and ambitious Eskil W. Swenson poses with his Model T during a sales trip through the winding roads of Tennessee’s Smoky Mountains

Eskil’s Future Takes Shape

Swenson spent his early career travelling across the nation “peddling” rock crushers and prospered. However, after the stock market crash in 1929, Swenson fought through the economic hardship of The Great Depression. Around 1935, Swenson was contacted by the Director of the Rockford Sanitary District to help manage solid waste disposal, because of his expertise with pulverizers. A new design which he called the «Triturator» was born, developed, and tested with incredible success.

Seeing this as an opportunity, Swenson soon began Swenson Spreader Manufacturing in 1937 under the original name Cherry Valley Pulverizer Company. He launched the business on his family farm along Mulford Road in rural northern Illinois. In 1938, Eskil W. Swenson was issued patent #2,122,965 for the “Triturator.” In 1939, the company relocated to Lindenwood, Illinois, where it operated out of C.B. Strang’s former garage, located very near today’s Swenson operation.

A Safer Solution: Swenson’s Spreader Revolution Begins

By 1940, “Eck” had developed the idea for a spreader that was designed to be mounted on the back of a truck or car to spread cinders for winter ice control and or sand for summer seal-coat work. Dorothy Swenson Otto, Eskil’s daughter, said about material spreading at the time, “The accepted method of spreading sand and cinders onto icy roads was to have a workman stand on the load in the dump body and shovel the strips of aggregate onto the road below. Ironically, a tragic winter accident in Elgin, Illinois, catapulted the potential for sales of my father’s simple and safe invention. A workman standing on the back of a truck shoveling sand onto the road fell to his death when the truck slid at an icy intersection.”

The city of Elgin, Illinois became Swenson's first sale.

During the period from 1940 to 1962, the primary product sold was the Swenson Chain Drive Spreader. Swenson Spreader Manufacturing continued to expand production and in 1962, Swenson introduced their first hydraulic spreader. Over the next few years several new models were launched, with E. W. Swenson holding many of the original patents.

A Major Breakthrough in Salt Spreader Technology

A persistent problem that plagued municipalities and commercial operations since the early days of road maintenance was controlling material spread at varying vehicle speeds. Accurate salt distribution was a constant concern. Not only for road safety but also for environmental and cost-related reasons. Unpredictable spreading often led to under-salted roads and increased safety risks, while oversalting was both environmentally damaging and very expensive.

Before 1967, the chain-drive system was the most accurate method available. It worked by connecting the spreader to the truck’s rear wheel via a mounted clutch. Because there was a direct relationship between the truck’s speed (wheel revolutions) and the spreader’s output, the faster the vehicle traveled, the more material it dispensed. However, this system was far from satisfactory.

As Richard F. Otto (Swenson’s sales manager and Eskil’s son-in-law) explained, “E.W. always wanted something better. He knew there had to be a better answer. He hired an engineer from Barber-Colman to work with him and the other engineers and designers in the Swenson shop. They focused on developing a method of automated control.”

Eventually, the team succeeded in creating a system using two synchronized sensors: one connected to the speedometer cable and the other to the feed mechanism. These sensors regulated the amount of material being spread by responding to impulses from the speedometer cable, allowing precise control based on vehicle speed.

Richard Otto recalled, “This is how we got into automated controls, and this was a really valuable patent because nobody else was doing it. We were the only ones in the industry to use this idea. To see it work so accurately was really amazing!”

Early block diagram of the Swenson automated spreader control system.

A Legacy of Excellence, A Future of Innovation

Eskil W. Swenson's legacy is not only etched in the patents he held or the products he created, but in the enduring spirit of innovation he inspired. His relentless curiosity and visionary mindset transformed a business into a hub of creativity and progress. As Eskil’s granddaughter, Lisa Imhoff recalls, “He wasn’t like everyone’s grandfather, Eck was endlessly curious, always building or dreaming up something new. But more than anything, he was a wonderful and generous man.”

Swenson Products continues to operate in Lindenwood, Illinois. For more than 75 years, Swenson has delivered top-tier snow and ice control equipment to municipal, government, and private markets. In September 2015, Swenson Products, became part of the Aebi Schmidt Group. Swenson remains committed to innovation, performance, and reliability, keeping roads clear and communities safe, season after season.

Lisa Imhoff

Lisa is the eldest of Eskil Swenson’s three granddaughters. She grew up on the family farm in rural Cherry Valley, Illinois—the same land where her mother and grandfather, Eck, were raised.

A graduate of Illinois State University with a degree in crop science, and the University of Wisconsin–Madison in art, Lisa followed her passion into graphic design, inspired by Eck’s vintage marketing materials. Like her grandfather, she enjoys photography and is dedicated to preserving the Swenson family history.

We're grateful to Lisa for keeping the Swenson legacy alive by generously sharing her grandfather's story.

Eskil Waldemar Swenson (March 23, 1901 – April 20, 1978)

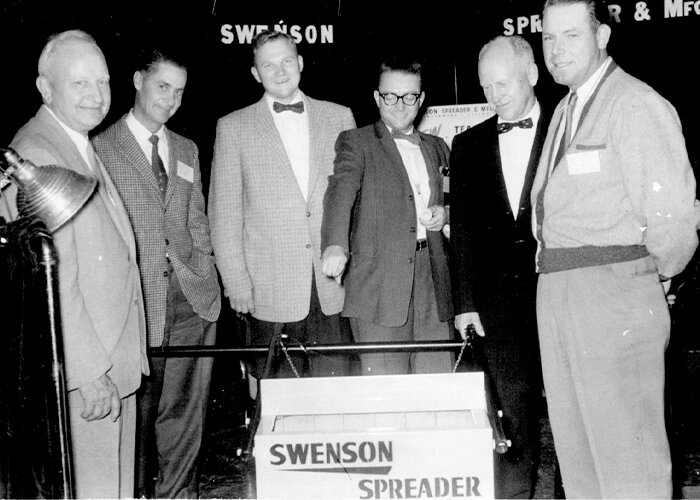

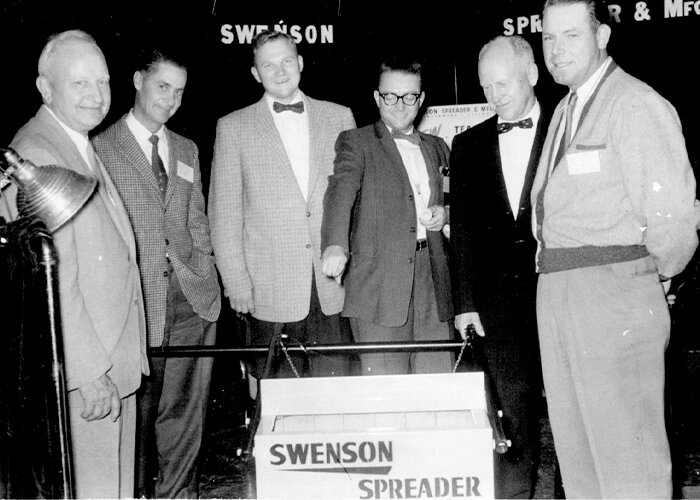

At a Roofing Convention, circa 1958. (Left to right): Eck Swenson; R.A. Swanson; Sturges Rfg. Mfg., Hartum, Colo.; Richard F. Otto (Eck’s son-in-law); Glenn Johnson (Eck’s nephew); Philip Swenson (Eck’s brother); Jay J. Sturges, Sturges Roofing Co.